The regular price is the current manufacturer's recommended price!

Company NÁSTROJE CZ, s.r.o., established professional cooperation with the University of technology in the year 2007, concretely with the Institution of engineering technology at the Faculty of mechanical Engineering, where its new drills CZ002 were put through the longtime testing.

Information about the new type of the metal drills CZ002 were published in the 9th copy of MM Industry Spectrum in 2007, where until that time, the almost unknown company NÁSTROJE CZ, s.r.o., from Kyjov, introduced them. These drills are already on the market and are kept on stock in the sizes from 0,30mm up to 16,00 mm.

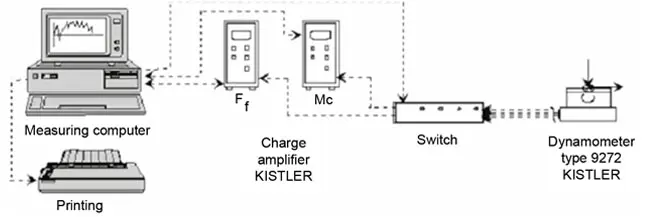

Pict.no.: 1 Diagram of measuring through the use of piezoelectric systém Kistler

Tests of the drill force load

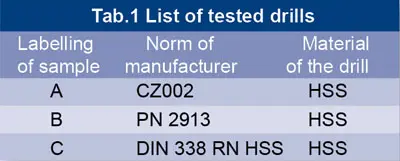

Currently there was one stage of the tests completed. There were short-term tests of force load of drills CZ002 carried out. At the same time there was carried out a comparison of drills CZ002 with the drills produced according to the domestic norm PN 2913 and the International norm DIN 338 RN HSS made by two top czech manufactures, which replace these drills. The aim of these tests was the comparison of cutting features of drills by the help of short-term tests of their force load, expresssed by the help of feed force and cutting moment. List of the tested samples and the conditions of the cutting test are stated in the tabels. For measuring of the feed force and the cutting moment there was used a Piezoelectric silicon dynamometer Kistler 9257B, equiped by Charge amplifiers Kistler 9011A, fully controlled by PC. (Pict.no.: 1).

Tested types of drills went in the short-time cut test and achieved results are possible to compare with the referential cut tool with the labelling A. Cut test lied in the record of feed force and cutting moment when drilling first na afterwards every next 10th hole from the total 122 holes by each tested tool. The choise of cutting coditions resulted from the recommendation of the producer for referential cutting tool and these conditions were for the whole time of the test constant. According to the agreetment requirements the drilling of each hole was proceeded without interrupting up until the depth 3xD = 18mm.

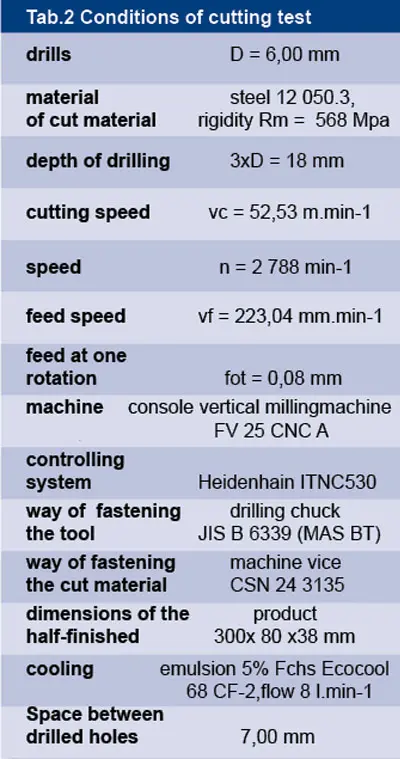

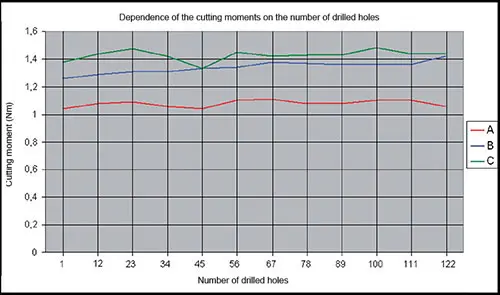

Pict.no. 2: Test results

Results

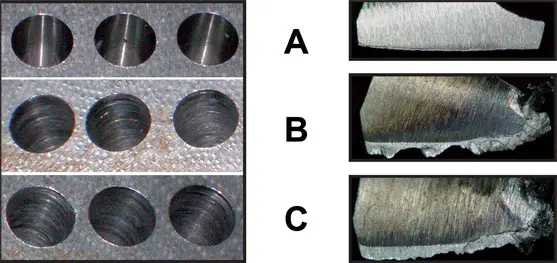

By anylysis of the force load there was found out, that the lowest average rate of feed force when drilling all holes showed the drill with the labelling A,drill CZ002 (pict.no.:2). The lowest average rate of the cutting moment when drilling all holes, showed also the drill with the labelling A, that means again CZ002 (pict.no.: 3). Morover the holes cut by the drill with the labelling A, showed essentially higher geometrical exactness and significantly lower roughness of the machined surface as compared with the holes cut by drills with the labelling B and C, which showes the evidence of it great stability and a very good chip disposal...

Pict.no.: 4 The tests were lead by doc. Ing. Miroslav Piska, Csc.

On the bases of the stated results, it is possible to say, that the drills CZ002 significantly exceeded till now used drills PN 2913 and DIN 338 RN HSS, not only in the both monitored values, but also in the geometric exactness and in the surface quality of the drilled holes.

Ing. Emil Nečesánek

NÁSTROJE CZ, s.r.o., Riegrova 399/2, 697 01 Kyjov

Business office Dobruška: Křovická 1047, 518 01 Dobruška; Tel.: +420 491 615 785; GSM: +420 777 581 299

E-mail: objednavky@nastrojecz.cz; URL: obchod.nastrojecz.cz