The regular price is the current manufacturer's recommended price!

Company Nastroje CZ, s.r.o., has put its longtime experience into the development of the new types of the spiral ground drills with straight shank according to its own developing line CZ. The aim of the company is to develop and produce comprehensive range of drills for various groups of machined materials, whose geometry will guarantee not only high geometric exactness of drilled holes, but also achieving long lifetime and durability of drills and thereby also productivity of work.

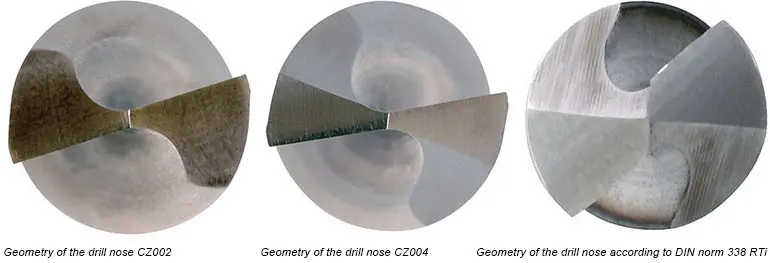

Is it still possible to change something on the geometry of the standard metal drills? Of course, it is. At the beginning of May 2007, after almost 12 months of intensive development and tests not only in the onwn test room, but also in the plants of the end users, the company Nastroje CZ, s.r.o., brought out two new types of metal drills from its own development line CZ under designation CZ002 and CZ004.

Drills CZ002

Drills CZ002 replace most worldwide spread and thereby most used drills designated according to the international norm DIN 338 RN HSS or domestic norm PN 2913. The uniqueness of drills CZ002 isn´t in the different material used for their production (it is standard steel CSN19830 or DIN W.Nr.1.3343), but in the new, absolutely revolutionary geometry of the complete tool. The nose of drill CZ002 thanks to is optimum chosen geometry significantly brings higher stability to the drill even when drilling at high cutting speeds and at the same time guarantees high dimensional and geometric exactness of the drilled holes. Very thin core, which is constant in the certain lenght of the front part of the drill CZ002, significantly reduces magnitude of necessary axial force for drilling and following heat build-up with the maintaining of big drill rigidity thanks to the multiple increase of the core thickness in the direction to the nose of the drill CZ002. At the same the revolutionary geometry of the core of the drill CZ002 gives a possibility of its resharpening with keeping repeatedly same geometry of its nose. Drills CZ002 are intended not only for steel drilling up to the rigidity 900 Mpa, but also for non-ferous metals, like aluminium and its alloys, brass and copper.Drills CZ004

Drills CZ004 were developed especialy for drilling holes into the tough steels resistant to corrosion and they differ from drills CZ002 not only by modification of the geometry of their nose, but also by using multialloyed materials for their production, which contain especially 5% cobalt (steel DIN W.Nr.1,3243, M35) or 3% vanadium (steel DIN W.Nr.1,3355, HS 6-5-3). Drill CZ004 replace drills produced according to the interantional norm DIN338 Rti HSSCo5 and DIN 338 RN HSSCo5 or according to the domestic norm PN2907. These drills were in the past and still are referred to as universal for drilling into stainless and high-strenght steels. Its wide core is at the nose lightened by special cross relief type C according to the DIN norm 1412. When the nose adjusted in this way enters the material, it badly centralize the drill, the material is discomposed and „dances“, thereby especially the geometry exactness of drilled hole suffers. Secondary lips created by cross cutting relief tend to a quick dulling, which leads to the necessity to expound extensive axial force for next continuation of drilling .The result is a big heat build-up, which leads to the fast wear-out of drill cutting edges and thereby of its resharpening with keeping repeatedly same geometry of its nose. Drills CZ002 are intended not only for steel drilling up to the rigidity 900 Mpa, but also for non-ferous metals, like aluminium and its alloys, brass and copper. course to its very short lifetime. Moreover because of the special geometry of nose relief, it is very difficult practically, considering the standard equipment of companies, to repeatedly resharpen the drill with required exactness.

Advantages of the new geometry

The new geometry of the metal drills CZ002 and CZ004 minimalize the above described lacks.The result of drilling is the exact, fine machined hole without a necessity of preboring, at the substantialy higher cutting conditions and the substantialy higher lifetime compared to the above mentioned current drills. Not less important is the fact, that the drills CZ002 and CZ004 are possible to regrind with achieving repeatedly the same geometric exactness. Drills CZ004 are intended for drilling especially stainless, high-speed and tough high-alloy steels with the tensil strenght up to 1200 Mpa. Advantages, which are brought by the new geometry of drills CZ002 and CZ004 are proved by the award from the 14th International Machinery Fair in Nitra (Slovakia), where the drills were awarded by the Award for the new generation of metal drills. The revolution of the new geometry of the drills CZ002 and CZ004 is proved also by the fact, that in the Czech Republic for this geometry of drills there was a Certificate about the registration of the utility design given, which is filed under document number 17537 and under mark file PUV 2007-18528. The aplication for the European patent is filed under number EP07005754. Drills CZ002 and CZ004 currently create the bearing production programme of the company Nastroje CZ, s.r.o., and are on stock in the diameters from 0,30 up to 16,00 mm.

Ing. Emil Nečesánek

NÁSTROJE CZ, s.r.o., Riegrova 399/2, 697 01 Kyjov

Obchodní kancelář Dobruška: Křovická 1047, 518 01 Dobruška; Tel.: +420 491 615 785; GSM: +420 777 581 299; E-mail: objednavky@nastrojecz.cz; URL: obchod.nastrojecz.